About Us

about us

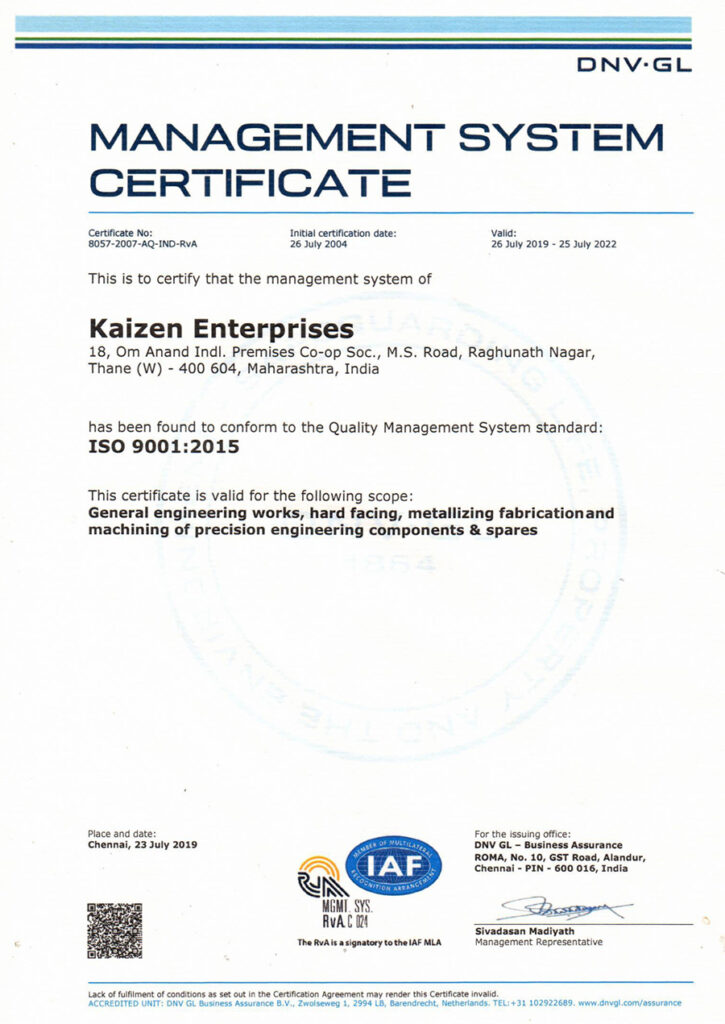

Kaizen Enterprises

The “Kaizen Enterprises” is promoted by three qualified Engineers having vast cumulative experience of 26 years in the field of Hard facing, Metalizing of various components.

The organisation established in 1998.

| Name of Organisation | M/s Kaizen Enterprises |

| Year of Establishment | July1998 |

| Constitution | Partnership |

"Kaizen" Stands for

A continuous improvement process designed for prolonging the life of all stationary and moving parts with the low heat input process. These products and processes help industries

Project scheduling

Reclaim worm / damaged components at a fraction of the cost of new components.

Prolong the working life of old as well as new components.

Reduce inventory-carrying cost and down time cost resulting in increased productivity and profitability.

"Kai" means "Change"and "Zen" means "For the better". Change for the better becomes an ongoing process when every person keeps making improvements (no matter how small) continuously.

"Kaizen" edge points

Low heat input => Minimum distortion.

Extra strength for maximum safety .

Chemistry of metalizing and service life improves internal structure of protective coatings for maximum wear resistance.

Construction materials

Possible to apply even on contaminated metal.

Prevention of down time.

Low annual maintenance cost.

Services

In the field of low temperature repairs and maintenance welding technology. Also in break down, preventive and protective maintenance welding accompanied by economical cost and saving analysis.

Services to carry out the jobs with great precision and accuracy so as to share your responsibility.

Services to carry out the job in actual ‘CITU’ condition without dismantling the system so as to save your cost on down time.

We also ensure quality with third party inspection.

We have a wide range of measuring instruments to carry out the jobs with great precision and accuracy.

| 1 | Verniers | 06″ (Digital) 06″ 12″ 24″ | 3 nos. 3 nos. 3 nos. 2 nos. |

| 2 | Dial Vernier | 12″ | 2 nos. |

| 3 | Bore Dials (mm) | 17 – 35 50 – 150 150 -300 300 – 400 400 – 500 | 1 no. 2 nos. 1 no. 1 no. 1 no. |

| 4 | Micrometers (mm) | 0 – 50 50 – 150 100 – 150 150 – 200 200 – 250 250 – 300 300 – 400 400 – 500 500 – 600 | 1 no. 1 no. 1 no. 1 no. 1 no. 1 no. 1 no. 1 no. 1 no. |

| 5 | Dial Gauges | – | 4 nos. |

| 6 | Dial Indicator | – | 6 nos. |

| 7 | Temp. Measuring Device | – | 2 nos. |

| 8 | Hardness Testing Machine | – | 1 no. |

Welding Machines

| 1 | Arc Welding Machine | 1 no. |

| 2 | Mostek make TIG Welding Machine | 1 no. |

| 3 | MEMCO make Pulse TIG Welding Machine | 1 no. |

Machinery

| 1 | 7′ Lathe Machine | 2 nos. |

| 2 | 5′ Lathe Machine | 3 nos. |

| 3 | 6′ Lathe Machine | |

| 4 | Tool Post Grinder | 1 no. |

| 5 | Pedestal Drilling Machine | 1 no. |

| 6 | Pedestal Grinding Machine | 1 no. |

Thermal spraying

| 1 | M.E.C. make SUPERJET 100 torch | 4 nos. |

| 2 | L & T make EUTALLOY | 1 no. |

| 3 | L & T make ROTOTEC gun | 1 no. |

Note: We carry out calibration periodically.

Strength of Organization

| Engineers | ||

| 1 | Welder (NPC,BHEL,LLOYDS Approved) | 3 nos. |

| 2 | Turner | 4 nos. |

| 3 | Helper | 3 nos. |

Type of Coatings

| 1 | L&T | 6 | Spray Met |

| 2 | Hoganas | 7 | Advani Fon |

| 3 | Wall Colomonoy | 8 | OM6 American |

| 4 | Union Carbide | 9 | Weartech |

| 5 | Zircast |

Alloys of Nickel and Cobalt, Fusibles and Non-Fusibles like Chromium Carbide, Boron Carbide, ceramics, cermets, oxides, etc. Pure Nickel, Chrome, Moly, Sn, Ti, S. S., Al, Cu, Monel, Inconel, Hastalloy, Polymer, etc.

We carry out non-destructive testing of each and every job to ensure quality (for blow holes, pin holes and cracks, etc.)

Jobs undertaken :

| 1 | Pump Casing & Impeller Wear Rings | 9 | Extruder Screws |

| 2 | Shaft Sleeves | 10 | Valve Seats & Wedges |

| 3 | Bushing Diffusers | 11 | Motor Shafts |

| 4 | Balancing Discs & Counter Discs | 12 | Turbine Blades & Nozzles |

| 5 | Balancing Drums | 13 | Wire Drawing Rings, Pulleys & Dies |

| 6 | Drum Liners | 14 | Engine Parts |

| 7 | Heat Exchanger End Plates | 15 | Fly Wheels |

| 8 | Centrifuges | 16 | Crushers, Hammers & Cutting Knives, etc. |

Registration Nos.

- VAT TIN No. - 27670052299 V w.e.f. 01/04/06

- CST TIN No. - 27670052299 C w.e.f. 01/04/06

- W.C.No. - 400604/W/1136 w.e.f. 1/10/01

- SSI Reg.no. - 112484151